Grippers

|

Photo Gallery Coming Soon  Video Gallery Coming Soon |

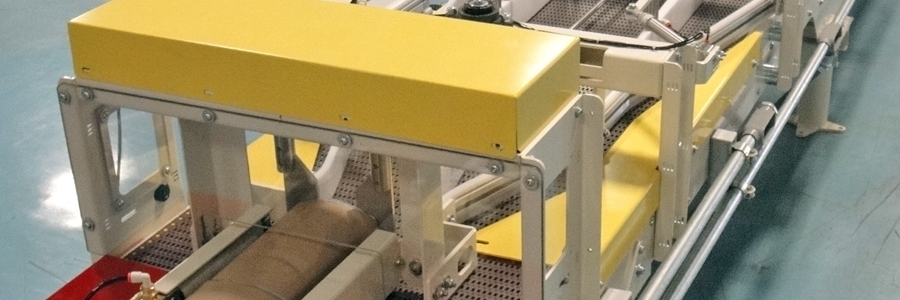

These units have been a staple in industry for a long time. When your requirements need you to elevate your product to free up floor space, a Gripper Elevator has been a choice for many. The same unit can be used to bring your product back down to ground floor. This unit will grasp your product along its sides and power it to the elevation that is required.

These units can be made in a variety of sizes and radiuses depending on your specific product that you have. At CPW we will recommend the right unit for your application. All the units are width adjustable via a hand wheel; all the units can be upgraded to have a motorized width adjustment for those automated systems.

While mostly used for elevating and lowering products in an "S" shape, these units can also invert products using the "C" style Gripper. When discharging a "C" Gripper the top becomes the bottom and vice-versa. Also available are Gripper Upenders which incorporate two (2) independent "L" shaped Gripper sections that when interfaced with each other can change the orientation of the package by laying it on its side.

All Gripper units can be fitted with an adjustable base. This base can adjust the in-feed and discharge height of the Gripper together the same distance. The adjustment is made via a hand wheel through jacking screws.

All Grippers are available with different styles of gripper bulbs as well as different durometers. At CPW we will make sure that we propose the right bulb for your application.

Laners

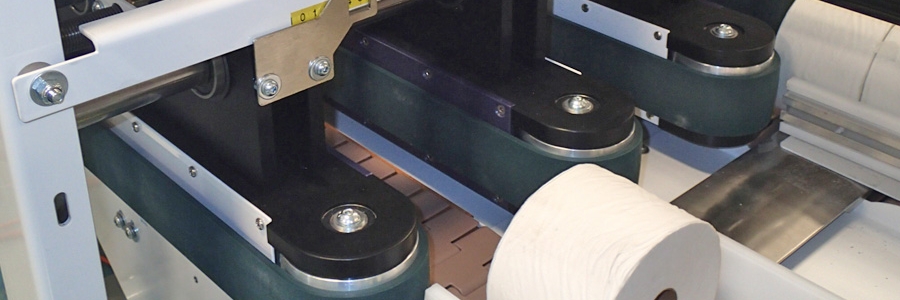

Laners (sometimes called Diverters) are an integral machine for most production lines today. Laners are used to take a single or multiple input lanes of product and disperse them into multiple discharge lanes. Typically the distribution to the discharge lanes is balanced but can at times be a ratio of products to lanes due to the limitations of the downstream process equipment that particular lane is feeding.

There are both Servo operated Laners and Laners that are operated pneumatically. Typically the Servo Laners are for high speed applications. We have been capable of processing 600 products per minute in a single lane in-feed format.

Most Laners utilize some type of metering system at the in-feed to create a gap between a specified count of products. This gap is used to make the switch to the various discharge lanes. At CPW we use "Control Belts" to start and stop the products. These are powered by some type of motor whether it is an AC gearmotor or a servo motor. In some cases where rate is not extreme and cost is a concern, the Control Belts can be replaced with pneumatic stops and clamps. Servo Laners include a gate that moves between the discharge lanes from the in-feed lane(s). This gate is powered by a servo motor that is attached to a linear actuator. This provides for a smooth, fast and accurate movement of the gate. The gate is a heavy duty channel design which operates in a straight line fashion (not an arc) at the discharge for smooth transfer of the products from the Laner onto the downstream conveying system.

Within the Servo Laner the Gate and the Control Belts are width adjustable for all the different products that will run through the unit for your particular application. Typically this adjustment is via a hand wheel, one for the Gate and one for the Control Belts, however, servo motors can replace the hand wheels for a totally hands free change over.

Pneumatic Laners are typically our Paddle Style. These units have multiple lane infeeds and multiple lane discharge points. These Laners also utilize Control Belts at the infeed which are the top/bottom style and not the side by side as used on the Servo Laners. In this case the top belt only adjusts up and down for the size product you are running. This adjustment is done via a hand wheel. These Laners use a number of pneumatically operated paddles to steer the products through the unit. If you have a preference to avoid using air on your Paddle Laner, we can exchange the air cylinders with electric actuators. While these units are designed to distribute a balance of products to the discharge lanes no matter what is happening at the infeed, it can also send a ratio of products to the discharge lanes depending on the downstream requirements.

Overhead Sweep

|

Photo Gallery Coming Soon  Video Gallery Coming Soon |

Overhead Sweep

Product Orienting

|

Photo Gallery Coming Soon  Video Gallery Coming Soon |

CPW's experience with product orienting systems include the formats listed below. For more detailed information about each system format please follow the red arrow to the right of the dropdown menu, or contact us for further assistance.

Subcategories

-

Equipment-Accumulation

Equipment-Accumulation