Personnel Access

|

Personnel Access - Gallery  Video Gallery Coming Soon |

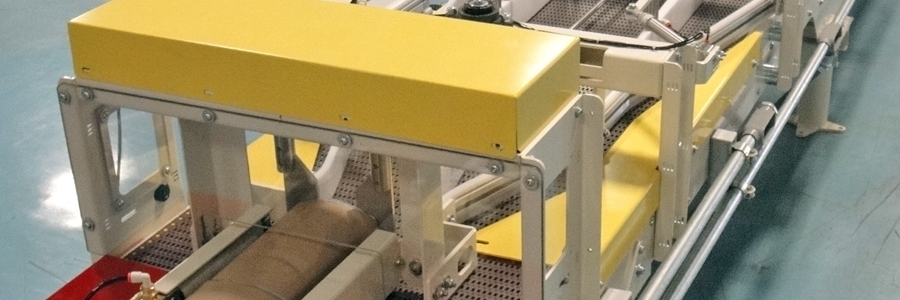

Most production lines remain at floor level and do not elevate overhead. In these cases it is necessary to provide access through the line for personnel or equipment. This is accomplished with Lift Gates or Retractable Conveyors. Both of these units are effective pieces of equipment for providing the necessary access through the line.

At CPW we design our Lift Gates to be easily lifted by your personnel. We have designed our Lift Gate with a counterweighted system which assists in the lifting process. The weight system is designed for the specific size Lift Gate that you require. If a self-powered lift is required so that personnel do not have to physically lift anything, an air cylinder or electric actuator can be used in place of the counterweight. These units are stand-alone units and can be self-powered or slave driven from an adjoining conveyor.

Retractable conveyors are becoming more common for creating access through a production line. This design allows the conveyor to slide into itself creating an opening for personnel. This is done with a bearing slide system and a special wrap of the conveyor chain. Opening the unit can be done by grabbing a handle and pulling or it can happen automatically by an air cylinder with a manual valve.

Arm Upender

|

{youtube}WGxDfxIrgsk{/youtube} |

These conveyors are your typical style of conveyor. These use a table top plastic chain that is either a straight running chain or a curve chain. These conveyors are used for transportation and accumulation. Upenders are used for changing the orientation of a product 90 degrees by rolling it clockwise or counter-clockwise. At CPW we offer two styles of powered Upenders, an Arm style and a Twist Helix. Both styles are effective but the Twist Helix is much more reliable and easier to set up if runing a variety of products.

The Arm style Upender is a cogged belt with a highgip cover over it. The Arm is angled and cantilevers over the transportation conveyor that it is mounted along side. The product is steered to the edge of the conveyor where it will then engage with the Upender Arm and the product will travel up the Arm changing its orientation. Once the product leaves the Arm the product will have changed its orientation by 90 degrees. Speeds of the Upender Arm and the transportation conveyor are critical for proper upending. It is necessary for the transportation conveyor to keep driving the product into the Upeder Arm to keep it engaged with the Arm. If the Arm is lowered out of the way, the products are allowed to pass by without changing the orientation.

The Twist Helix is our more common tool for upending product. This unit uses two strands of rollerbase table top chain which form an "L" shape to cradle the product. As the product moves through the Helix, the chains will twist 90 degrees changing the orientation of the product. During the twist of the chains, the bottom chain at the infeed becomes the side chain at the discharge and vice-versa. The chains are under tension via a air cylinder, this assures that the chains will run smooth as these operate without any catenary. Our Twist Helix is totally enclosed for safety and includes hinged access doors.

Rotators

|

{youtube}http://www.youtube.com/watch?v=JP7UzWio3Jk{/youtube} |

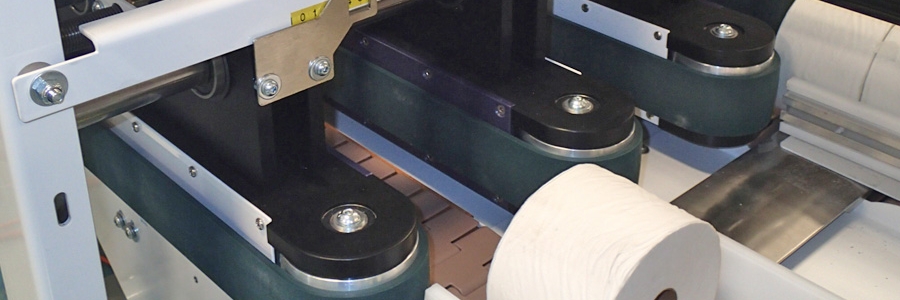

At CPW we have a couple of different ways to rotate your product, the most common being a Dual Belt Rotator. This unit uses two similar modular plastic belts that are side by side with one of the belts running faster than the other. This change in speed forces the product to rotate about the centerline changing the orientation of the product 90 degrees. This unit can rotate products 90 degrees clockwise, or 90 degrees counter-clockwise. We can also rotate 180 degrees if required. Our standard unit has both belts cant at around 5 degrees, this promotes good product contact which provides for the best results with soft sided product. If running hard sided products like cartons or cases there is no need to cant the belts, they should remain flat. This unit is capable of rotating packages up to a rate of 250 products per minute.

Horizontal starwheels are another style of Rotator that can be used for changing the orientation of your product. This is a positive style of Rotator which is powered by a gearmotor or a servo motor. This can run in an indexing mode or a continuous mode depending on your application. The starwheel will be designed based on your specific product requirements.

Starwheel

Starwheel - Gallery |

|

| {youtube}q8EmD8wtj3A{/youtube} |

Starwheels are a very common piece of equipment for changing the orientation of a product, typically a flat surfaced product like a carton. Starwheels can also be used on some soft sided products, but this application would need to be reviewed prior to providing a quote.

Starwheels will "roll forward" a product changing its orientation 90 degrees, basically the top of the product becomes the leading edge. At CPW we can design the starwheel that will best fit your product requirements. The starwheel design is based on your specific product, in many cases we can design a starwheel that can accommodate a variety of products so there is no change over. If your products vary too much, we will design as many starwheels as necessary and provide you with the means for quick changeover.

Starwheels can be powered by AC gearmotors, or in high speed applications we apply servo motors for improved control. With servo powered starwheels we are capable of reaching speeds in excess of 550 products per minute. This rate is product sensitive and requires a stable flat sided product.

Starwheels can also be gravity powered. This is done with back pressure either horizontally (level) or on a decline. A friction pad is used as a brake to assure that the starwheel does not free spin too easily.

If your variety of products do not need all of them to engage with the starwheel we can design it so that the starwheels can drop out of the way allowing products to pass through with changing orientation. This can be accomplished by a handwheel or it can be powered up and down via an air cylinder or electric actuator.

Subcategories

-

Equipment-Accumulation

Equipment-Accumulation