Stainless Steel - Modular Plastic Belt

|

||||||

| {youtube}p1Dwl0StrMo{/youtube} |

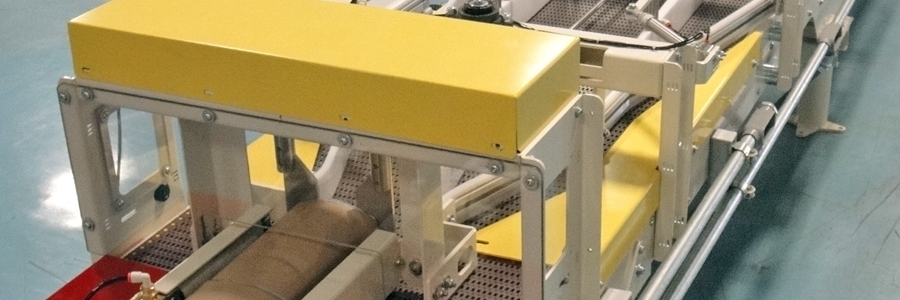

These conveyors use a plastic hinged belt that can be made into a number of different widths. Some widths are molded to width or MTW. These conveyors are used for transportation and accumulation. The conveyors can be manufactured in stainless steel type 304 or 316. The plastic belts are available as a straight running belt or as a side flexing belt that is used to go around curves.

Our modular plastic belts can be manufactured in an "open top" style which is the most common style. We also manufacture these conveyors as a "closed top" or sanitary design. This design is used in clean applications where the conveyor is exposed to a wash down.

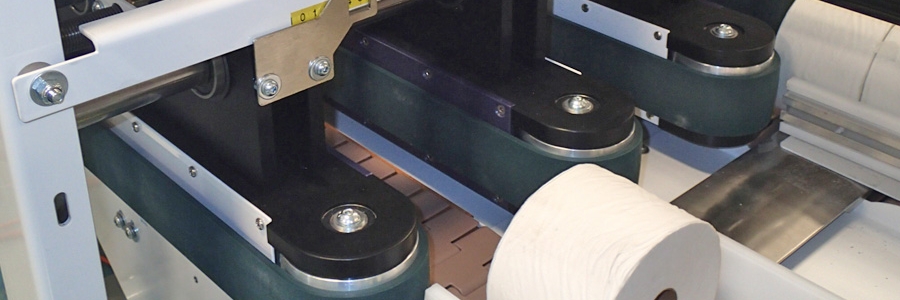

The plastic belts that are available can be customized with cleats, side walls rollers or friction inserts. These are for special situations like inclines and declines or reducing back pressure. The plastic belts are also manufactured in a number of different materials depending on the application. The most common is some form of acetyl material which offers a low coefficient of friction between the product and the plastic belt. The other materials can reduce the coefficient of friction, increase the coefficient of friction, provided as "anti-static" or even abrasion resistant to name a few.

These conveyors can operate at a number of different speeds. Special considerations need to be made when exceeding the 200 fpm speed with the side flexing plastic belts.

These considerations include conveyor layout and curve wear strip material. The straight running plastic belts can reach speeds in excess of 500 fpm.

While table top conveyors are still very common, plastic hinged belts are becoming more and more common as they do run much quieter at higher speeds and many of them are available in a pitch length that is less than 1.5" which is the common pitch length of table top chains. Some belts get down to a 1/2" pitch length and are made with scalloped bottoms which allow them to go over a small noser for a continuous transfer of products.

Mild Steel - Core Handling

Core Handling - Mild Steel

Mild Steel - Uni-Frame

CPW has developed the latest in modular conveyor systems for industry. This unique open style conveyor was designed for applications where dust can build up causing complications with the function of the chain.

This unique open style universal frame design can accommodate any combination of the 882 series table top chains; 4.5”, 7.5”, 10.0” and 12.0”. We don’t stop there, this frame can also accommodate any width of hinged plastic belts, from 3.0” through 60.0” and wider. The flexibility still goes on, we also offer this unique modular design with a variety of wearstrip materials; UHMW, oil impregnated wood, nylatron and many others.